Main application:Repair and strengthen workpiece surface, significantly

Welding method:PTA welding

Main equipment:PTA welding machine

Flame core temperature: about 10000℃

Technological characteristics:PTA has high temperature, concentrated energy, stable combustion, small heat affected zone, fast welding speed, high production efficiency, easy to obtain low dilution rate of surfacing layer, surfacing layer and workpiece matrix are metallurgical bonding,, bonding strength is high.

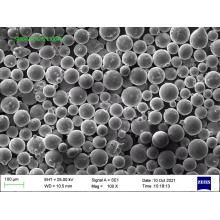

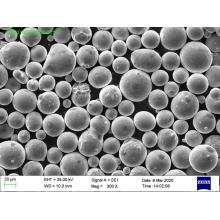

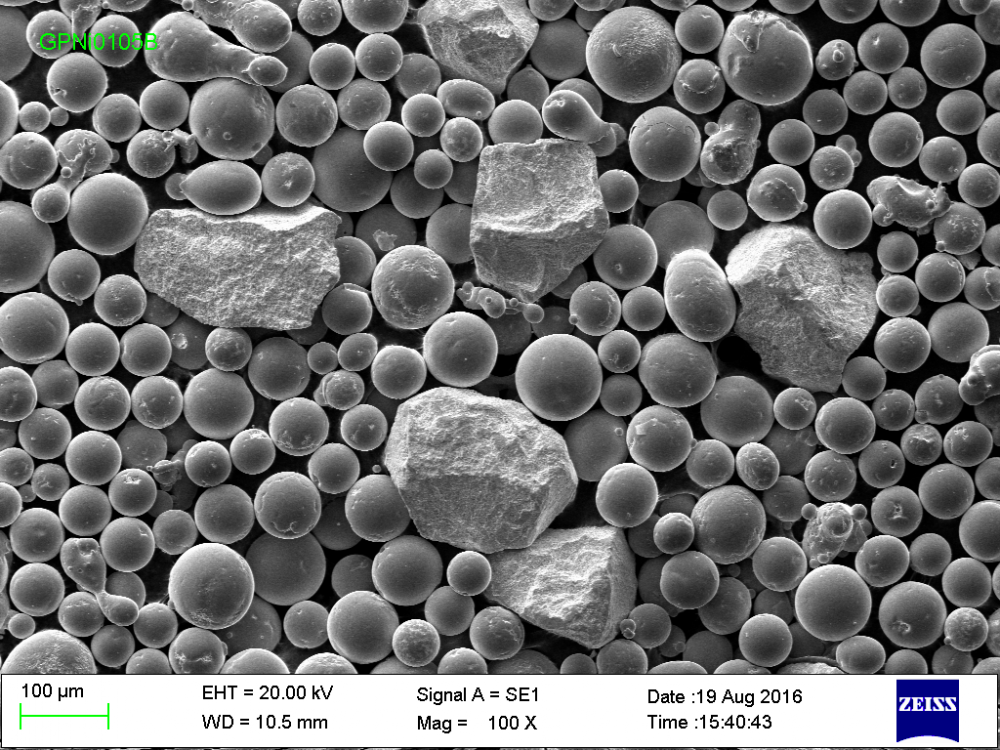

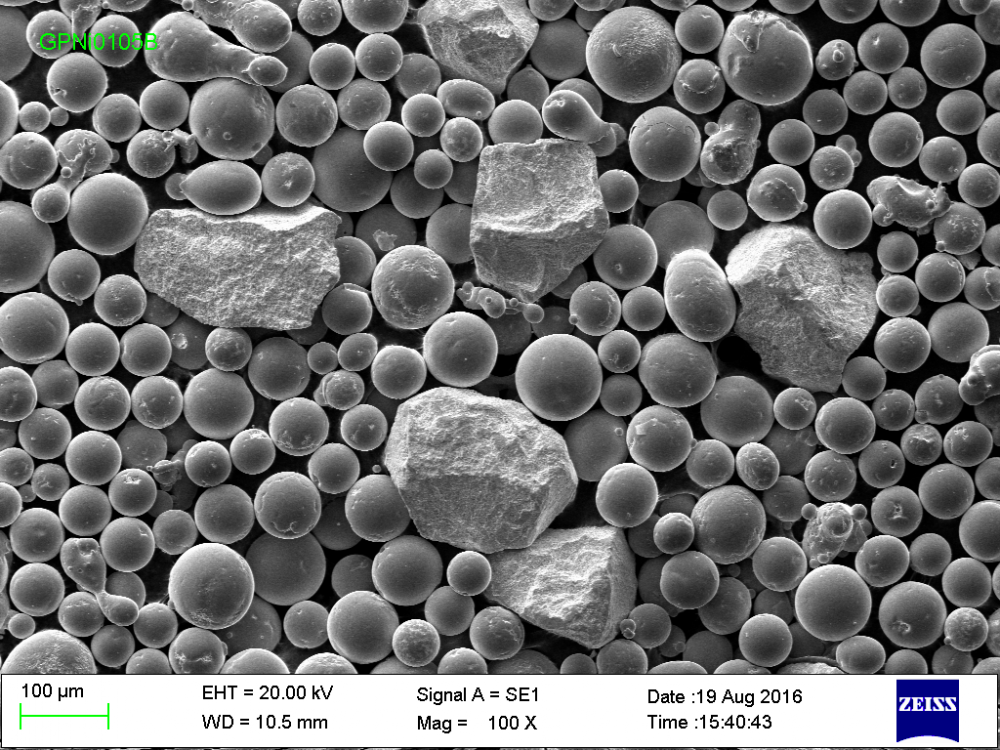

PTA welding technology is one of surface strengthening methods, which has high deposition rate, low dilution rate, and could be applied with many kinds of powder. The manufacturing craft of PTA Powder is normally gas atomization, which reduces satellite of powder. We supply 4 main categories of PTA powder: Nickel-based alloy powder, Iron-based alloy powder, Cobalt-based alloy powder and Mixed Powder.

Nickel Based Alloy Powder possesses high temperature resistance and wear resistance, it is the most popular alloy powder applied by PTA welding both domestically and internationally. Coating hardness is within the range of HRC 30-60. It could be applied to various industries like agriculture, plastic, paper, marine and steel making where wear and corrosion protection needed. Some examples are plunger, moulds, pump leaf and screw.

Iron Based Alloy Powder is more widely used and a more economic choice. With high abrasive resistance, it is more commonly applied to mining tools, drilling tools and mixers of iron and steel making industry, coal industry, shaft, oil and energy industry.

Cobalt Based Alloy Powder is recommended for corrosion and oxidation resistance, with better hot hardness values than equivalent Nickel based alloy powder. It is widely applied to steel making industry, coal industry and mining industry.

Mixed powder mainly refers to NiCrBSi mixing with other hard-phase powder such as cast tungsten carbide and other cemented alloy powder, which allows the powder better hardness around HRC60 and excellent abrasion resistance.

Mixed powder is more often used for mining equipment for oil sands, lignite, oil drilling tools, excavator buckets, extrusion screws for plastic processing, grain and oil processing, etc.

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now